Long Engine Life Starts With Reiff

Place an Order | Contact Us | FAQ

- Why preheat your aircraft engine?

- Why buy a Reiff Preheat System?

- Engine Preheat Systems

- Ordering Info, Terms, Return Policy

- Replacement parts

- Accessories - hard wired power plug, cowling covers, remote controls

- Installation Instructions

- FAQ

- Warranty

- FAA Approval

- Customer Comments

- Prominent Customers

- Donations

- Magazine Articles

- Company History

- Contact Us

- Intro Page

| SYSTEM

SUMMARY

See Application List for detailed listing. Prices shown are for 120v. Add 25% for 220V See below for photos |

|||

|

|

Standard System | XP System | HotStrip Oil Sump System |

| Watts

per cylinder

Watts on oil sump |

50w

100w |

100w

200w |

None

200w |

Cylinder Temp Rise* Oil Temp Rise* |

81F 88F |

119F 128F |

37F 80F |

| How fast will it heat my engine? | |||

| How long does it take to install a system? | |||

| Add Oil Cooler Heater Option to any system | |||

* Temps are RISE ABOVE AMBIENT after 12 hrs, on our Cherokee 235 with Lyc 0-540. Aircraft was in our unheated hanger, the air inlets were plugged with foam rubber cowl plugs, the cowling was covered with a blanket which laid over the top and hung about halfway down the sides, and the sump had 9 qts of oil. The temperatures were obtained by a calibrated digital thermometer with a remote probe inserted between the top two fins on the center left cylinder, and a second probe dropped down the oil filler tube with the tip suspended at the 4.5 qt level.

HEATING TIME (F)

|

||||||

|

|

XP System

100w per cyl 200w on oil |

Standard System

50w per cyl 100w on oil |

HotStrip Oil Sump System

200w on oil |

|||

| ELAPSED HOURS | CYLINDERS | OIL |

CYLINDERS | OIL | CYLINDERS | OIL |

| 0 | 20 | 20 | 20 | 20 | 20 | 20 |

| 1 | 41 | 66 | 35 | 52 | 26 | 66 |

| 2 | 60 | 84 | 46 | 63 | 33 | 80 |

| 3 | 77 | 100 | 57 | 73 | 37 | 87 |

| 5 | 105 | 123 | 74 | 87 | 46 | 96 |

| 12 | 147 | 156 | 103 | 110 | 60 | 104 |

Actual temps on our Cherokee 235 with Lyc 0-540. Aircraft was in our unheated hanger, the air inlets were plugged with foam rubber cowl plugs, the cowling was covered with a blanket which laid over the top and hung about halfway down the sides, and the sump had 9 qts of oil. The temperatures were obtained by a calibrated digital thermometer with a remote probe inserted between the top two fins on the center left cylinder, and a second probe dropped down the oil filler tube with the tip suspended at the 4.5 qt level.

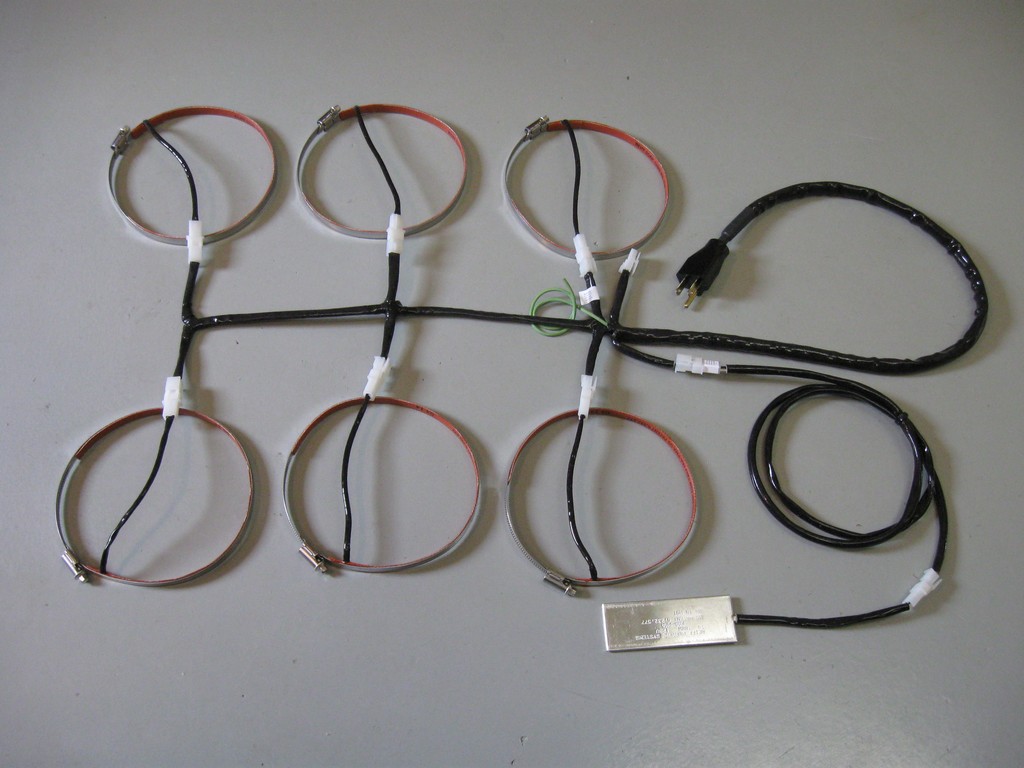

Standard System 50 watt band heaters clamp around the cylinders and a 100 watt aluminum HotStrip element epoxies to the oil sump (epoxy included). Heats your engine about 80F above ambient overnight. |

|

|

|

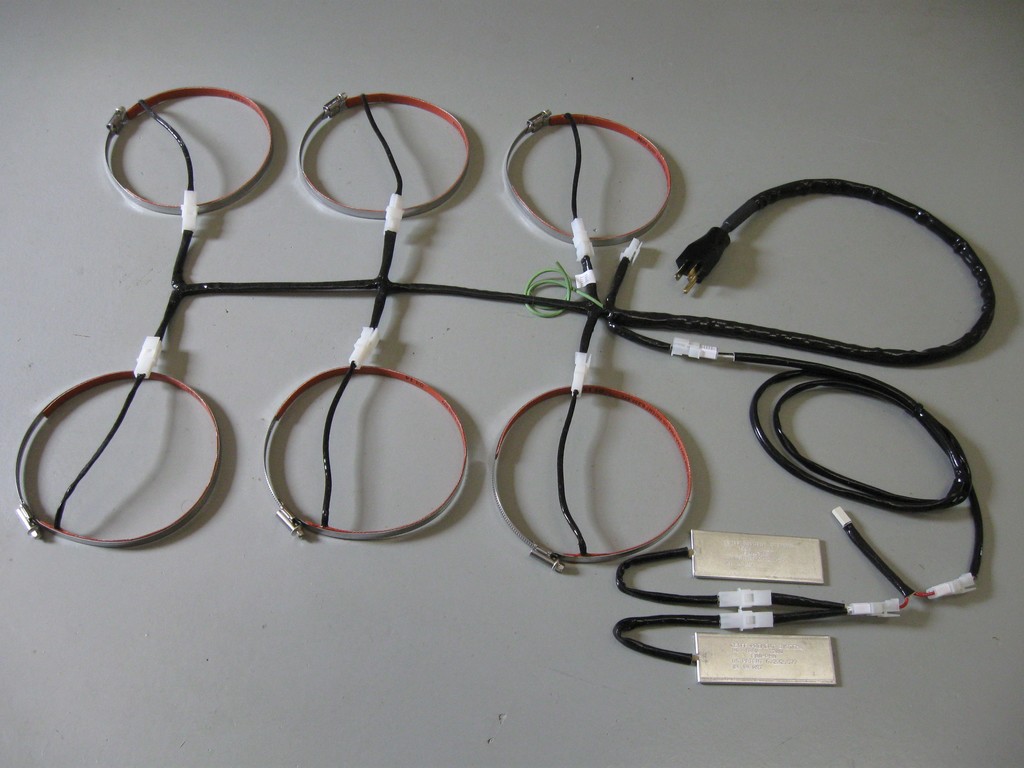

XP System XP means "Xtra Performance". This is our best system, doubles the wattage of the Standard System for faster heating and colder climates. 100 watts per cylinder + 200 watts on the oil sump. Heats your engine about 120F above ambient overnight. Thermostat limits oil to 190F APPLICATIONS LIST & ORDERING INFO

|

|

|

|

HotStrip Oil Sump Heater System Two 100 watt aluminum heaters epoxy to the oil sump. (Epoxy included) Thermostat limits oil to 190F

APPLICATIONS LIST & ORDERING INFO

|

|

|

|

Place an Order | Contact Us | FAQ

Last updated 01/08/2025

"And once you have tasted flight you will walk the earth with your eyes skyward,

for there you have been and there you long to return." Leonardo da Vinci